PHA: The Sustainable Polymer the World Has Been Waiting For

Polyhydroxyalkanoates or rather say Pure Hope for the Atmosphere, PHA is a remarkable class of microbially derived biopolymers that the world increasingly needs. These are next-gen biodegradable polymers well-known among sustainability researchers and soon, to anyone seeking scientifically sound alternatives to plastics.

What makes PHA worthy of its growing reputation?

PHAs are fully biodegradable including in marine systems and they’re highly biocompatible as well, capable of residing in the human body without eliciting adverse biological responses.

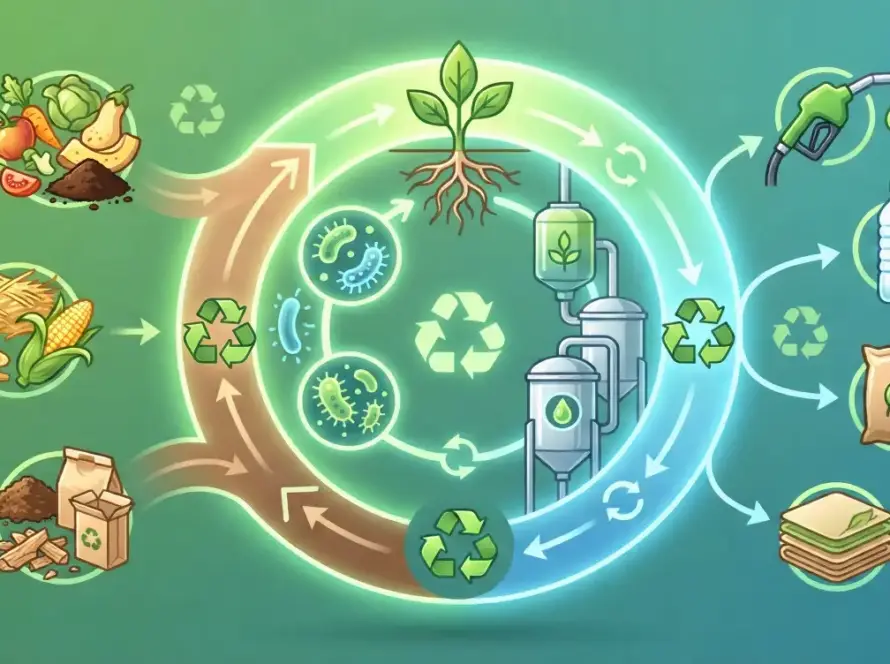

PHAs are essentially the intracellular carbon and energy storage materials which are produced by bacteria under nutrient-limited, carbon-rich conditions. In simple terms, when microbes encounter stress, they accumulate PHA granules much like organisms storing reserve energy.

Later these intracellular granules from the microorganisms are extracted to yield a polymer with all the functional properties comparable to conventional plastics, but with environmental integrity. PHA gets naturally degraded in soil, compost, and aquatic environments without requiring the industrial composting method or generating persistent microplastics. Its whole cycle is aligned with ecological processes, making it one of the most sustainable polymer families that is currently known.

No compromise on performance.

Depending on the monomer composition and chain length, PHAs exhibit a broad spectrum of material properties.

- Short-chain-length PHAs such as PHB behave similarly to polypropylene and can be rigid and crystalline.

- Medium-chain-length PHAs exhibit elastomeric and flexible characteristics.

This compositional adaptability allows PHAs to span applications ranging from stiff packaging materials to soft, rubber-like components.

How PHA is Produced

PHA is not conventionally manufactured but rather biologically cultivated.

Microbial cultures are supplied with carbon substrates like sugars, plant oils, waste frying oils, glycerol, and other renewable feedstocks. The major limiting essential nutrients (such as nitrogen, phosphorus, or oxygen) induces PHA accumulation.

After the fermentation process, the cells are harvested, the polymer is further extracted and purified, and the final material is processed into pellets.

Applications Across Multiple Sectors

PHA depicts broad applicability across several sectors due to its properties such as biodegradability, biocompatibility, and adaptability.

1. Packaging

It serves as a sustainable substitute for conventional plastics in items such as cutlery, bags, straws, cups, and compostable films, offering materials that can return safely to natural environments instead of getting accumulated in landfills and oceans.

2. Biomedical

Its compatibility with human tissues supports its use in sutures, tissue-engineering scaffolds, and controlled drug-delivery systems.

3. Agriculture

Its agricultural applications include biodegradable mulch films, seed coatings, and slow-release fertilizer carriers that reduce plastic residue and enhances the soil health as well.

4. Technology & Manufacturing

PHA is also growing in technology and manufacturing field, where it is incorporated into 3D-printing filaments, molded components, elastomeric materials, and other engineered products which require both functional performance and environmental responsibility.

However, the current reality presents challenges.

PHAs is still way more expensive than petrochemical plastics, and its processing particularly with brittle PHB can be technically very demanding. Its large-scale manufacturing infrastructure is still in the developing phase.

Yet the trajectory is clear.

With the increasing industrial adoption, governmental support, and intensified research, PHA production is becoming more cost-efficient and technologically improved. It is transitioning from an emerging material to a mainstream sustainable polymer.

Which takes us back to why is PHA “the polymer the world has been waiting for”

Because it is renewable, biodegradable, non- toxic, versatile, and actually a real solution. It shows that science can evolve in a gentler and kinder way.